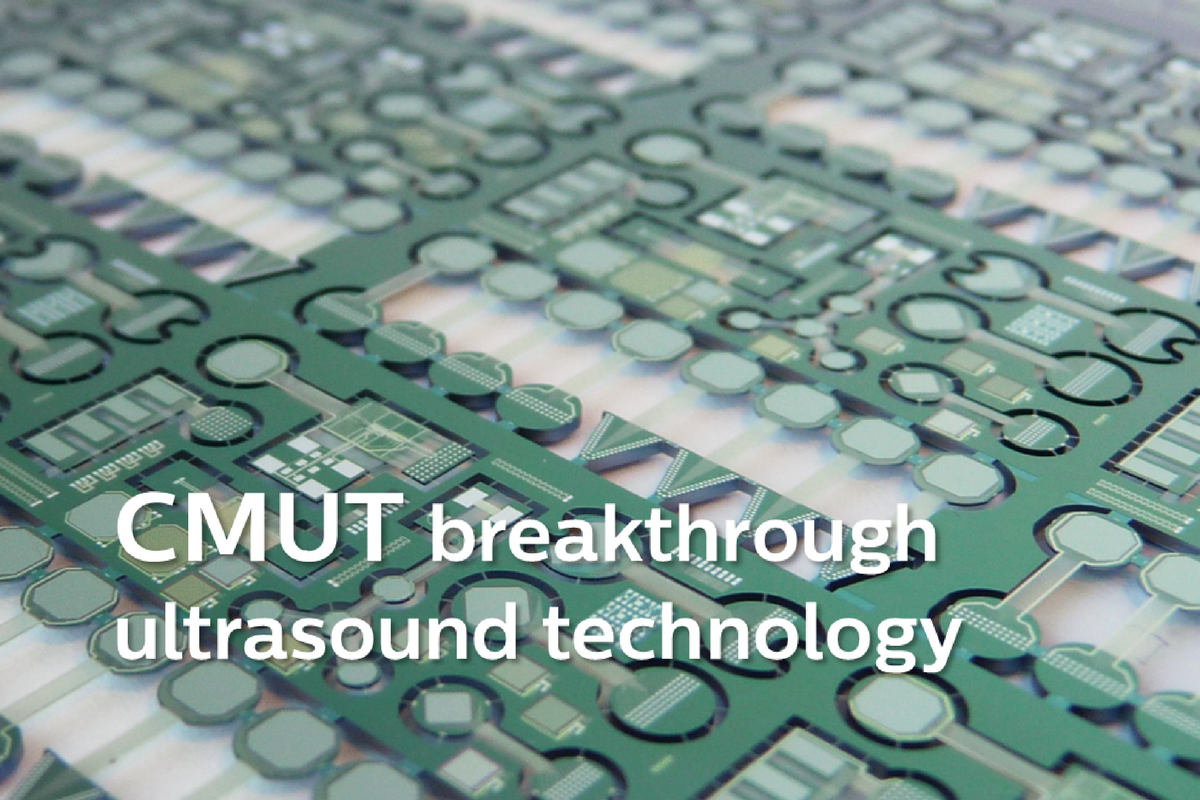

Capacitive micromachined ultrasonic transducers

What are CMUTs?

CMUTs – capacitive micromachined ultrasonic transducers – is a breakthrough ultrasound technology. CMUT transducers are MEMS based structures that can be used to transmit and receive acoustic signals in the ultrasonic range. They enable breakthrough applications for ultrasound technology in a diverse range of industries such as medical, microscopy, inkjet printin and testing among others. Compared to conventional technology, CMUT ultrasound transducers convey numerous advantages such as large bandwidth, easy fabrication of large arrays, and integration with driver circuitry: CMUT-on-CMOS.

Advantages of CMUT technology in manufacturing

On top of these advantages, CMUT technology offers a lot of design freedom, enabling your custom ultrasound MEMS device. Our experience in design and processing of CMUT devices enables us to support your custom MEMS device requirements. Our CMUT technology enables high volume ultrasound transducer manufacturing and high levels of integration at a lower cost. You benefit from our expertise, built from developing and manufacturing a range of CMUT array devices. Our CMUT technology platform shortens design cycles and therefore your time-to-market. Partnering with Philips Engineering Solutions is the quickest way to obtain a reliable CMUT device.

CMUT technology is capable of operating in a wide range of conditions:

- Temperature

-40 °C up to 200 °C (up to 250 °C with application-specific design). - Pressure

Up to 10 bar. - Abrasion resistance

Protective stacks available for various applications, scratch- and impact-resistant. - Chemical robustness

Resistant against substances like sulfuric acid (98%), ammonia water, sodium hydroxide, sodium oxalate, acetone, ethanol.

Exact device capabilities depend on design parameters and material choices. Our CMUT experts with over 10 years of experience are here to think along with you and make innovation work with clever new technology designs.

Direct contact

Paul Bekkers

Business Development Manager

Relevant reads

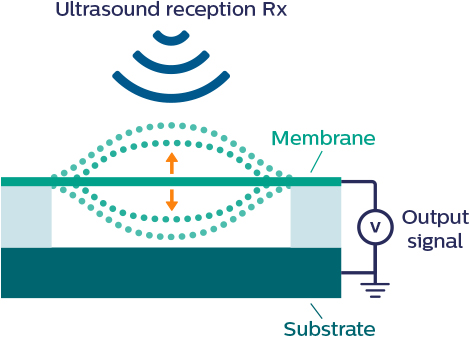

What is the principle of operation of a CMUT?

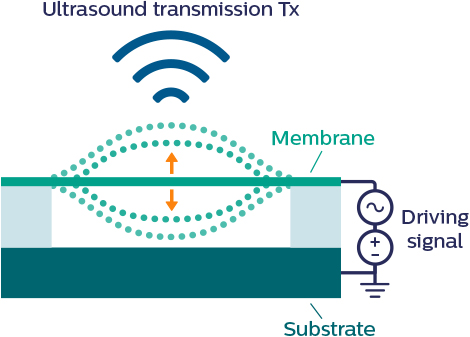

The basic element of a CMUT array is a parallel-plate capacitor. One plate is fixed, the other plate is supported by a flexible membrane. In receiving mode, an ultrasonic wave causes membrane vibration and a change of capacitance, which can be detected.

In transmitting mode, an alternating voltage is applied between the membrane and the substrate back plate. The resulting electrostatic forces cause vibration of the membrane, sending out ultrasound at the frequency of modulation.

Key features of CMUT transducers

- Frequency range from 500 kHz to 50 MHz

- Large bandwidth: over 100% in immersion

- Low mechanical coupling between elements, no crosstalk

- Integration with ASIC: CMUT-on-CMOS

- ROHS compliant, no toxic materials

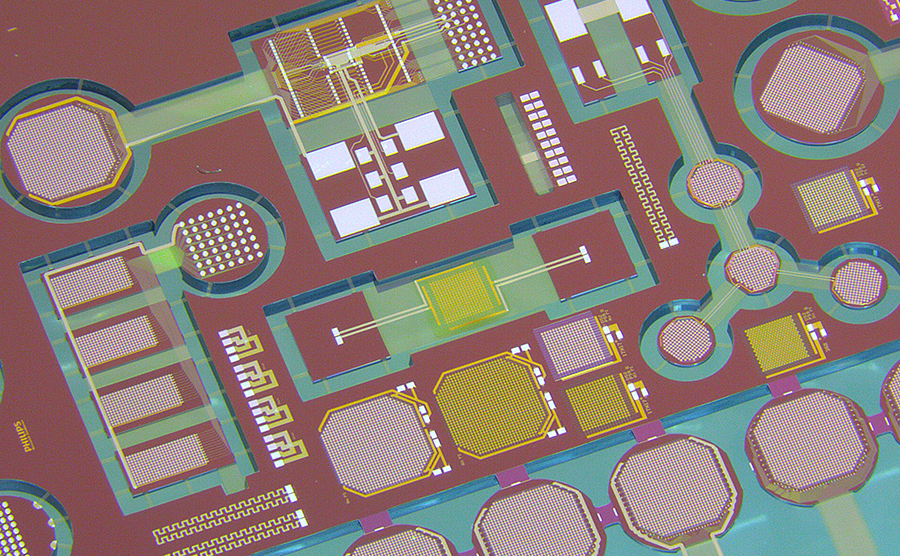

- Large range in numbers of CMUTs per array, array size, and array layout

- Easily attainable miniaturization, leading to a small form factor

CMUT application areas

- Medical imaging

- Medical therapy (high intensity focused ultrasound HIFU)

- ‘Smart’ medical instruments

- Nondestructive testing

- Ultrasonic flow metering

- Short range distance measuring

- Ultrasound microscopy

- Particle & fluidic manipulation

- Inkjet printing

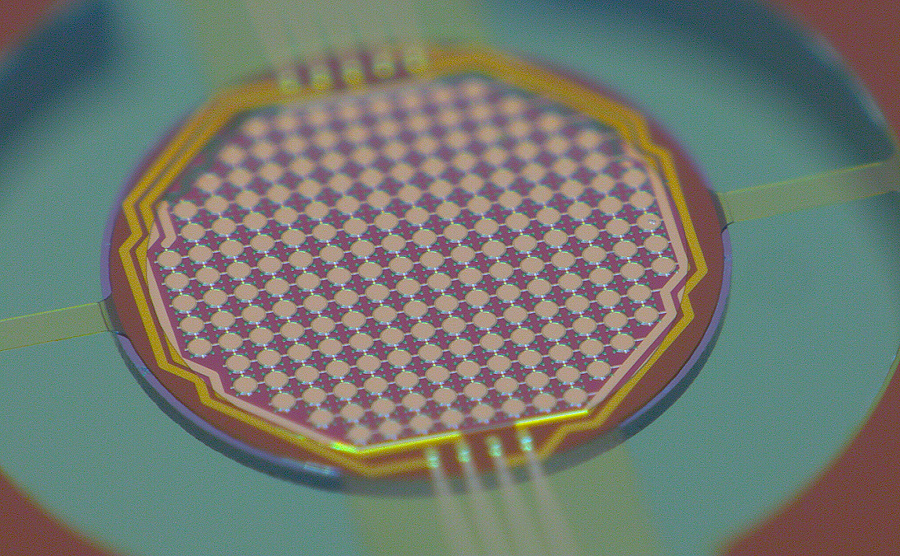

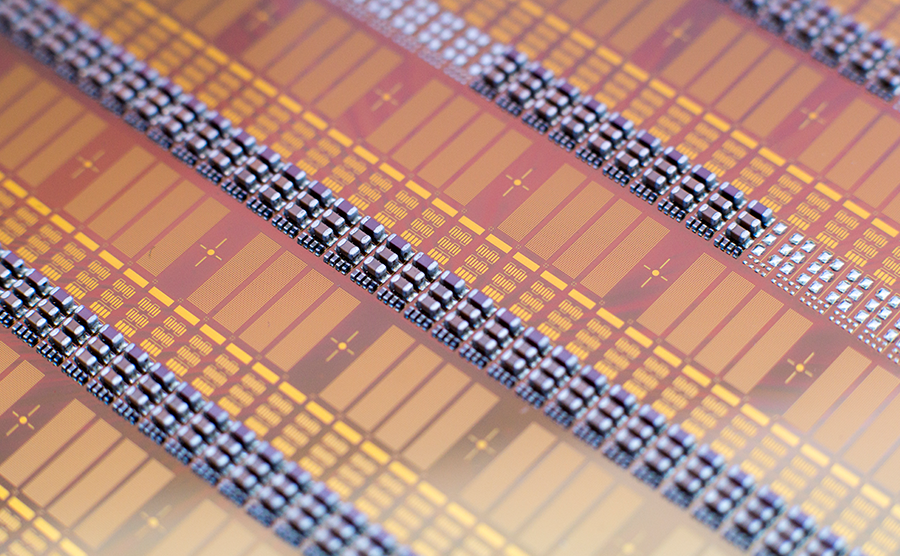

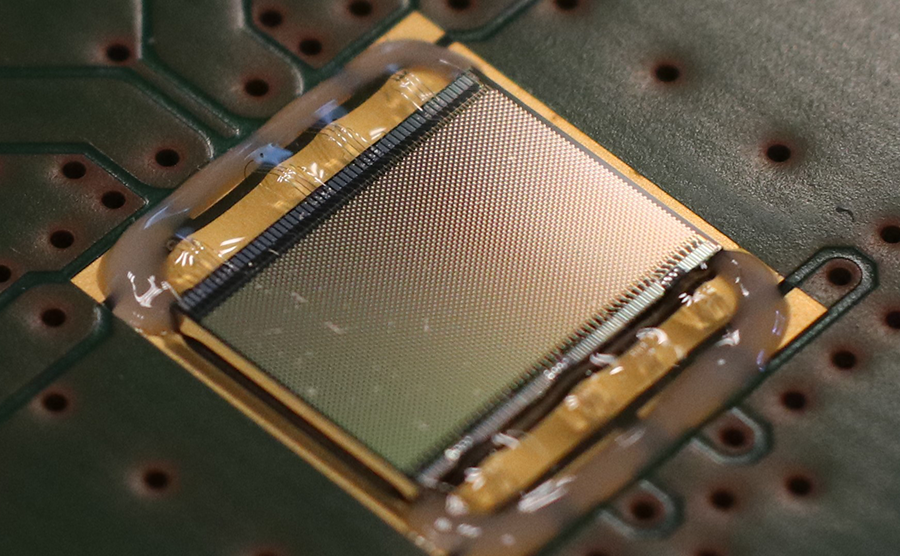

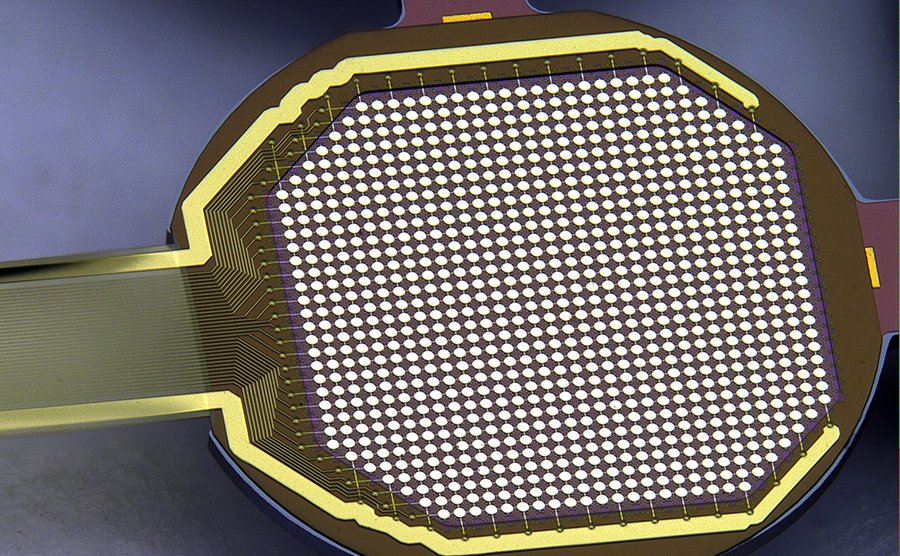

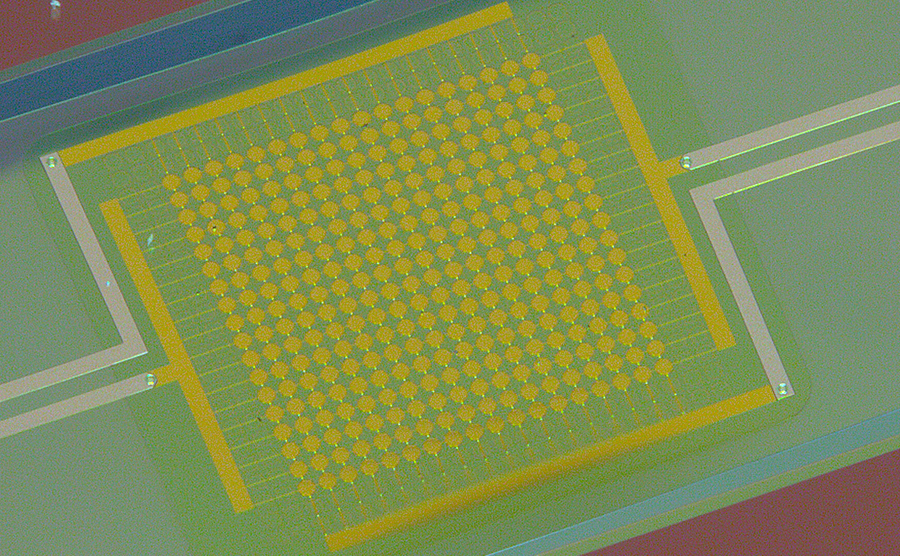

CMUT examples

CMUTs - Capacitive Micromachined Ultrasonic Transducers can be used in a series of industries and applications. Here you see some examples of CMUT arrays that we've developed together with our partners.

End-to-end, plug-and-play CMUT

With our extensive expertise, open development tools, and real-time access to data, combined with CMUT development capabilities, you are now able to quickly create, adapt, and commercialize innovative new ultrasound applications. The result? An end-to-end, plug-and-play package that can truly offer the fastest way to develop new innovations and bring them to market. Read the full article ›

Making innovation work: smaller medical devices

Nowadays, medical devices include a lot of different and specialized technologies. The access to these resources and technologies make it possible to make smaller devices, which help improve the heart procedures for the patients. Our MEMS team worked on a new MEMS technology for a catheter device. A device that has the potential to improve the visibility of the inside of the veins as surgeons perform less invasive heart surgery. This gives surgeons the possibility to perform the same procedure, but without having to open up the patient.

Hear Els’ story on how making smaller medical devices enables less invasive medical procedures ›

Innovation Engineering - with over 10 years of experience in CMUT technology

Imagine what could be possible with CMUT technology. Are you curious about new CMUT sensors and transducer technology? Are you interested in learning more about the design and manufacturing of CMUT devices? Are you on the lookout for the newest technologies in town?

Our CMUT experts are here to think along with you and accelerate your innovation with clever new technology designs. We have been working on CMUT technology for over 10 years now, and we are ready to share our CMUT knowledge with you.

Our CMUT experts deliver

- 10 years of CMUT experience – device design, combining customer’s application know-how

- State-of-the-art MEMS fabrication equipment with an experienced engineering crew

- Development of customized driver ICs, including specification, design, test and industrialization support

- Open development tools & real time access to data

- One single partner for a custom CMUT device from device and process concept development to volume manufacturing, integration and assembly services

- Pure-play MEMS foundry – for over 30 years working for industry leaders with high confidentiality and IP protection demands

- High customer satisfaction, NPS score > 50% (4.5 on a 5-point scale

Flex-to-rigid (F2R) for CMUT

In CMUT transducers, sensors and integrated passives can be integrated onto the silicon islands without the need for further assembly.

Let us help with your CMUT challenges

Paul Bekkers

Business Development Manager

Learn more about our services

Innovation Engineering operates a state-of-the-art 2650 m2 pure-play MEMS Foundry on the High Tech Campus in Eindhoven, the Netherlands. The MEMS Foundry is specialized in low to medium volume custom MEMS manufacturing.

Our 140 experts design, develop and manufacture custom microelectromechanical systems (MEMS) and assemble micro devices. We follow a phase-gated approach; from demonstrating feasibility and giving proof of concept, up to manufacturing your devices with the right quality.