Philips MEMS & Micro Devices

Our promise

We industrialize your innovative MEMS & micro-device design into a high-quality manufacturing process, and we produce your product in volumes.

We use a proven phase-gated development approach, with scalable industrial processes and technologies, leveraging our industrial tools and process libraries.

We apply design-for-excellence principles to address critical-to-quality parameters and processes.

We work in close cooperation with you through open communication.

Your benefit

Partnering with Philips MEMS & Micro Devices assures that your product is industrialized and manufactured with the required quality and reproducibility.

Reason to believe

Philips MEMS & Micro Devices will be your partner that brings decades of experience in serving highly demanding markets.

What is MEMS technology?

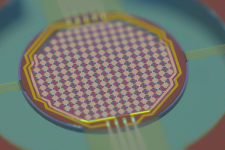

Microelectromechanical systems, or MEMS, is a process technology used to create tiny integrated devices or systems that have both mechanical and electronic components. The functional elements of MEMS are for example: minitiaturized structures, sensors, actuators and microelectronics.

Our MEMS Process capabilities

- We deliver more than 15,000 wafers per year from our ISO 5, 6 and 7 class cleanroom (equivalent to 100 – 10,000 FED standard class)

- We offer the flexibility to work with materials ranging from Ag to Zn, including ‘CMOS-forbidden’ materials, alloys, dielectrics and polymers like parylene.

Download the process capabilities overview ›

MEMS Foundry and Micro Devices Facility working as one-stop shop

We offer both MEMS foundry and Micro devices assembly as a one-stop shop, which allows our partners to have one point of contact for efficient communication and project handling. It is pretty unique that the two entities can collaborate together, within 5km distance in Eindhoven. MEMS component & micro assembly can really be optimized for each other at Innovation Engineering.

Innovation Engineering operates a state-of-the-art 2650 m2 pure-play MEMS Foundry on the High Tech Campus in Eindhoven, the Netherlands. This MEMS Foundry is specialized in low to medium volume custom MEMS manufacturing. When off-the-shelf components do not meet your requirements, and you consider having a custom MEMS device especially made for you, you come to us.

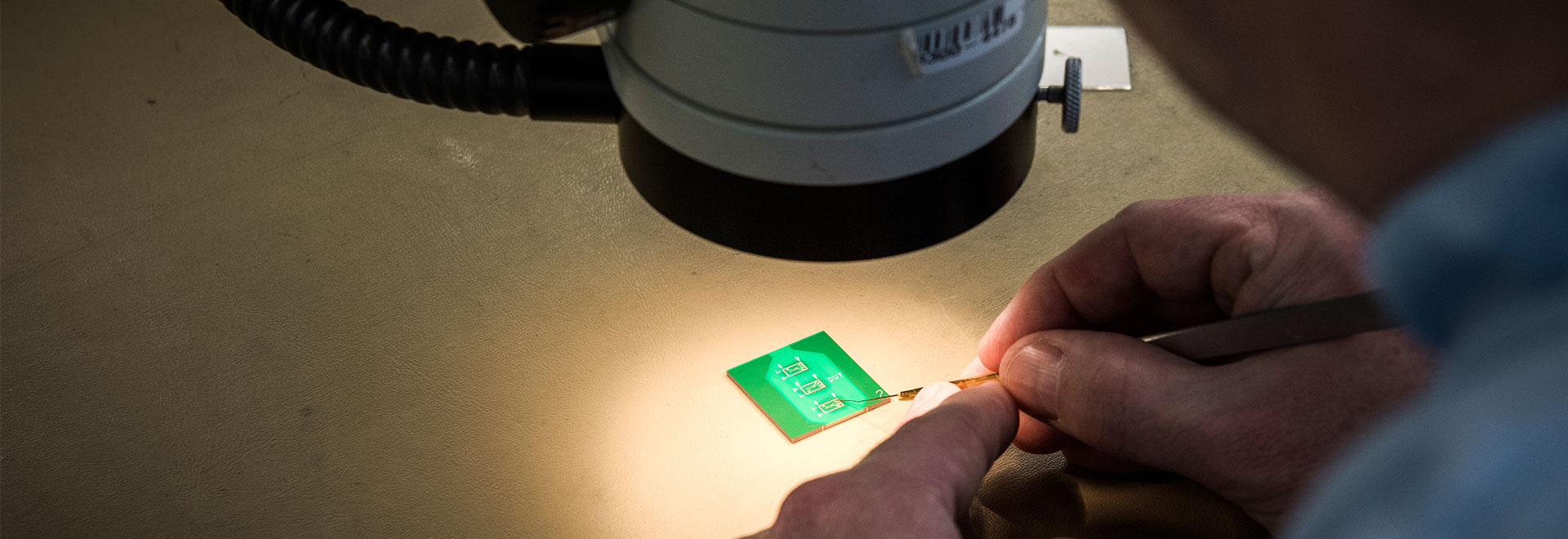

At the Micro Devices Facility The Greenhouse located at Strijp in Eindhoven, the Netherlands, we have over 40 years of experience. We deliver key microsystem modules, integrated into devices, for the medical & high-tech markets. Our customers typically require a complex combination of technologies to obtain new advanced functions at small scales.

Capabilities for MEMS & Micro Devices

- Assembly: die attach, wire-bonding, stud bumping, ACF bonding, pick & place and soldering

- Concept creation and technology scoping

- Continuous improvement

- Cpk analysis and yield improvement

- DfX: Design for eXcellence

- Functional testing

- Inspection and failure analysis: solder paste inspection, 3D automated optical, X-ray

- Mentor graphics lay-outing

- Risk management, FMEA

- Supply chain management

- TPD/DMR product documentation management

- Verification & validation of process and tooling

Key application areas

New digital printing application areas, breakthrough technology & cost advantage with custom thin-film MEMS inkjet printheads.

Breakthrough applications for ultrasound, complementing conventional technology with advantages.

Benefit from unique BioMEMS expertise that has helped leading BioMEMS companies successfully turn their imaginative ideas into working devices.

In house expertise to shorten your photonics development time and help you achieve consistent products at volume scale.

Paul Bekkers

Business Development Manager MEMS Foundry