RF applications

Are you active in the RF business, like in radar, RF power, communication, wireless connectivity, or RF testing? Are you developing products for high-frequency applications and striving for excellent performance and quality?

Excellence requires the optimal balance between competencies like electrical design, layout, component choices, board quality and assembly. You need the right tools and competencies to realize high-quality functional boards, modules or systems.

You will be needing high-quality systems, boards or modules for evaluation, characterization or even customer sampling, guaranteed to perform, so you can focus on finishing your development work with short iteration cycles to optimize your RF performance. Also, you may want to ramp-up and manufacture your products in volume. Obviously with high quality and at an efficient cost level, such that you can grow your business.

Typically you will want to focus on the design work and rely on a partner for the realization of these boards. That partner must understand your business and know what RF assembly entails. We are such a partner: geared up for the prototyping or manufacturing of high quality RF products.

We have been working in electronics assembly for over 40 years, and have collected a wealth of know-how on industrial design rules, substrate and interconnect technologies. We work for customers in the following RF application areas:

- Radar (e.g. for industrial, automotive, care management, defense, security)

- Communication (base stations, cell phone components)

- Connectivity (e.g. Bluetooth, Wi-Fi, Zigbee)

- RF power (e.g. radar, broadcasting, cooking, lighting)

What do you want to know about our micro-assembly for RF applications?

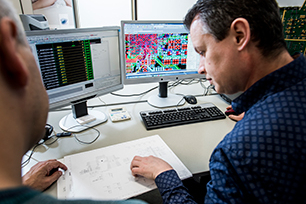

Do you want support in RF design, bringing expertise on modeling and simulation, lay-out, thermal management, EMC, antenna design, signal integrity, wireless reliability, and functional testing? Do you want to benefit from our end-to-end approach and work with a partner who has your end-goal in mind?

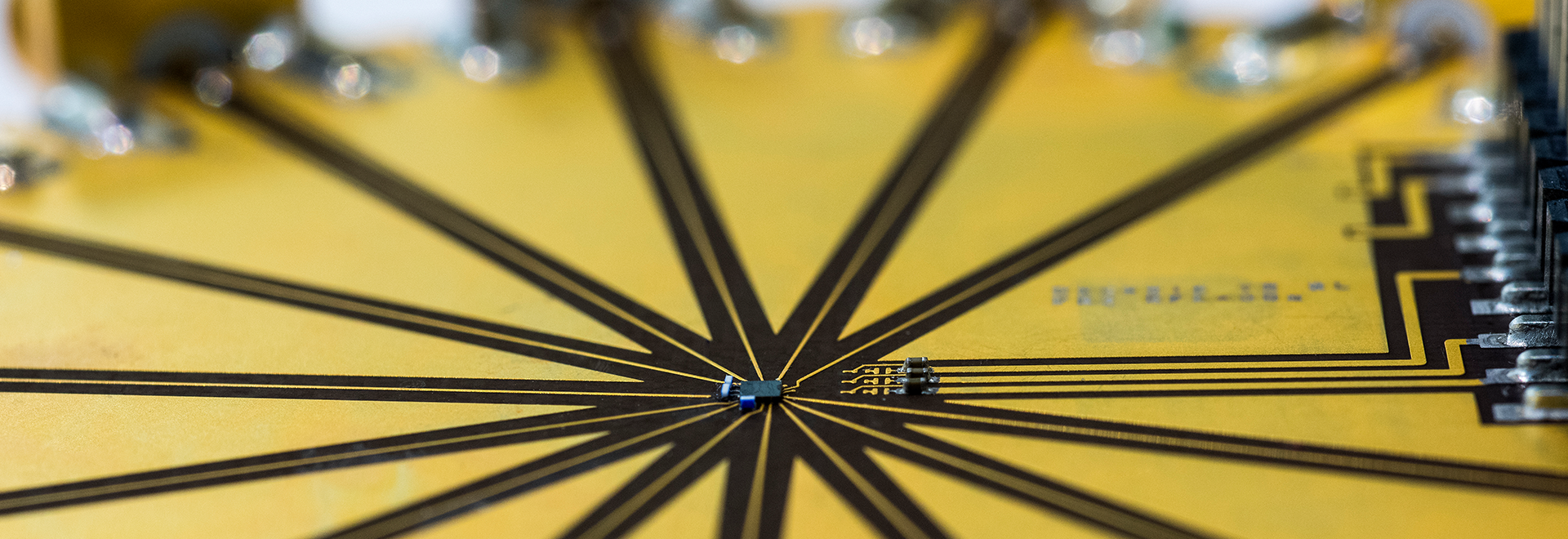

Is Design for Reliability and Manufacturing a must? Do you want access to state-of-the-art micro-assembly equipment for Surface Mounted Device (SMD) component placement, die bonding with accuracies down to 1.5 μm at 3σ accuracy, and wire bonding for Au and Al? Do you need high-end PCBAs or hybrid solutions created?

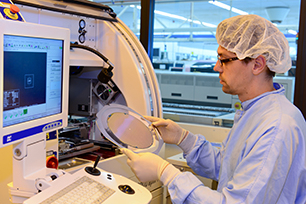

Do you need strict quality control and a guaranteed high quality? Is test and inspection equipment like 3D solder paste inspection, 3D automatic optical inspection, and electrical test and X-ray analysis on your wish-list? Together with our RF designers and EMC specialists who make functional test setups tailor-made per application, as RF requirements differ per device.

RF micro-assembly prototyping & manufacturing

RF prototyping

Working in RF requires a systematic approach in development, where design and assembly go hand in hand. Typically you work in phases, with evaluations in between. For that you need evaluation boards, or characterization or even test boards, and often you rely on a partner to make these boards for you. As development time is precious, you want short feedback loops on your design relying on high quality with quick turnaround times. This allows you to focus on finishing your development work and hitting the design-in windows at your customer.

Time to market – fast delivery of products (typically PCBAs) for purpose of evaluation, characterization, testing or demonstration:

- Low quantities, up to few 100’s

- High quality, i.e. 1st time right made with industrial equipment

- Highly qualified user (mostly the designer self)

- Rarely taken into volume later

Fast industrial prototyping – starting with your electrical design, and potentially a layout, we collaborate to understand the critical aspects of your product and define a process for prototyping. You benefit from our long history and vast experience in RF micro-assembly, as witnessed for example in our design rules and footprint libraries. Time to market, i.e. short turnaround time, first time right, and high-quality assembly is key for RF applications. Quantities are typically modest: 10’s to 100’s of units.

RF ramp-up and manufacturing

Your prototypes have been successfully evaluated, and the market is waiting for you to deliver products in volume. Dedicated engineering work, including aspects like component management, assembly and test development and yield engineering, enable a controlled ramp-up to volume. This allows you to have your products manufactured at high quality and yield, such that you can focus on growing your business.

Time to volume – step by step approach to a product that is made in volume:

- Quantities can be 100’s to 10,000’s

- High-quality PCBAs or modules

- Systematic approach, aimed at overall cost, yield

- Often starts with time to market work

Ramp-up and production – starting with your prototype product that you want to bring to market, we team up to understand your business goals in terms of quality, timing, volume and costs. Making your prototypes on industrial equipment, we are able to discuss aspects of Design for Manufacturing, component management, reliability, and testing right at the beginning of your design process. In a phased approach we will bring your product from prototype to qualification, and ramp it in a steep learning curve to the required volume and yield levels. This kind of work is typically about time to volume. Quantities will be in the 100’s to 10,000’s.

RF micro-assembly & design

Your assembled products will benefit from our know-how in RF micro-assembly. Aspects like design rules, component placement, thermal management, and reliability are an integral part of our way of working. Helping you to optimize your designs to specific for your business case. Our way of working allows us to follow you in an efficient manner

Choices in the beginning of your design phase will have a major impact on the quality of your product, cost price, time to market, yield and field call rate of your product in production. High quality and narrow process windows are a must for a high RF performance level of your product. This performance will benefit from an integral approach.

To maximize your benefits and minimize the costs and to prevent drawbacks we can combine your knowledge of the application and the RF performance with our expertise:

- Antenna design and simulation tools

- Design (lay-out, placement accuracy, design rules)

- Electrical design expertise on RF, analog/mixed signal and power management

- EMC consultancy and testing

- Failure mode and effect analysis (FMEA)

- Interconnect technologies: soldering, gluing, bonding, wire bonding, stud bumping, thermal compression, etc.

- Optimized inspection and testing strategy

- Standard component library including dedicated foot prints

- Testing and inspection

- Thermal simulation competences including models and simulation tools

RF micro-assembly in the spotlight

Micro-assembly services for RF applications

With over 30 years of experience in working with electronics production we have expert knowledge on industrial design rules, substrate technologies, and a complete portfolio of interconnect technologies. Our services range from fast prototyping, yet using high-quality industrial standards, to manufacturing of high-end PCBAs in volume. Should your design be of odd shape or require non-conventional substrates, our service in interconnect architecture & prototyping will be relevant. Click below for more detailed information.

Fast prototyping of RF boards, e.g. for evaluation, characterization, testing or demonstration. First time right, with high RF performance and industrial quality.

Manufacturing of RF boards in volume, with high yield and a fast and controlled ramp-up.

Interconnect architecture & prototyping

New RF solutions may require to combine ‘standard’ SMD technology with back-end technologies like die and wire bonding to create stable RF solutions in narrow process windows.