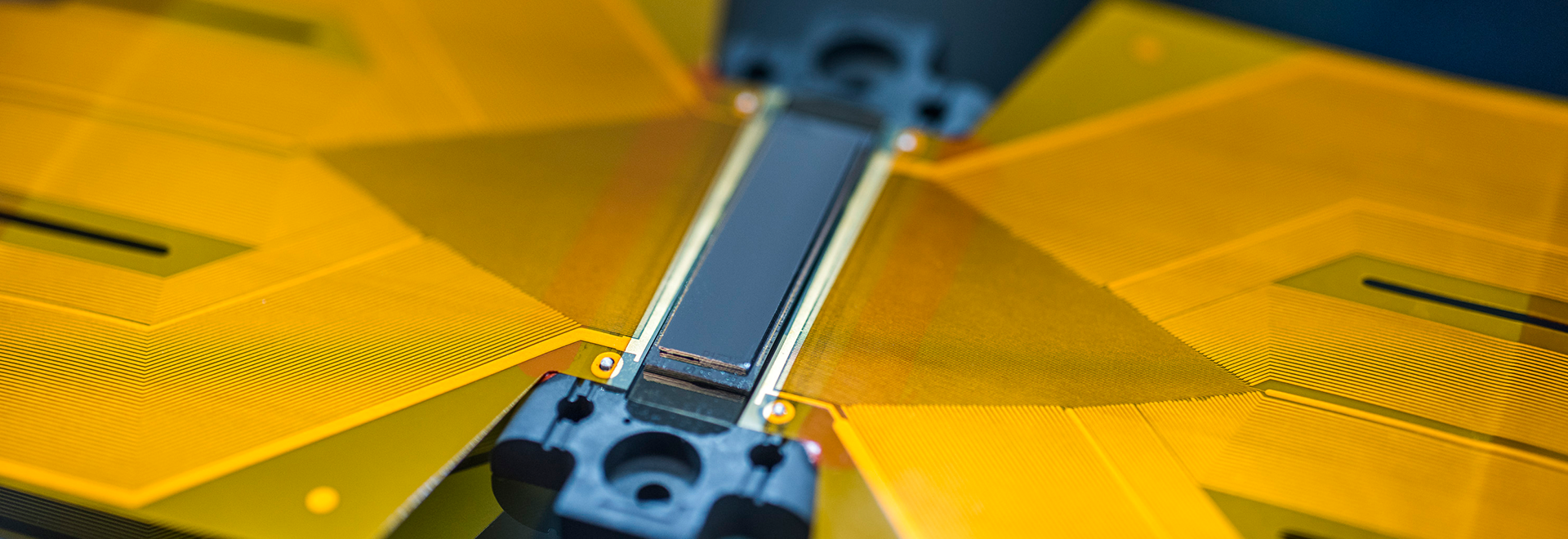

MEMS inkjet printheads

Inkjet printing technology is evolving fast. Are you considering the move from bulk piezo printheads to the usage of thin-film inkjet printheads? Thin-film PZT (lead zirconate titanate) opens opportunities for improving total cost of ownership (TCO). This inkjet technology also provides access to new digital printing application areas, such as large & wide-format printing or – next to commercial inkjet printing – the ability to design high performance industrial inkjet printheads.

Your MEMS inkjet printhead innovation opportunity

Are you looking to deposit novel inks on ceramic, organic, polymer or even aqueous materials? Interested in single-pass precision micro-deposition of functional fluids on exotic materials? Such as electrode materials for flexible electronics, photovoltaics and optoelectronics? These breakthrough inkjet applications together represent a bright diversified outlook for a potentially disruptive inkjet printing business.

Custom made printheads versus off-the-shelf

Are you an inkjet OEM or print head assembly manufacturer? Are you contemplating the fabrication of an innovative thin-film printhead device to meet new market requirements? Do you need to create a sustainable competitive advantage in inkjet technology?

Off-the-shelf silicon MEMS piezo printheads may be faster, but custom devices can ensure the needed competitive inkjet technology advantage and cost edge. When an off-the-shelf thin-film piezo MEMS printhead solution just does not seem to assure your sustainable advantage, a custom thin-film PZT MEMS inkjet printhead might be worthwhile investigating.

Custom MEMS inkjet printhead fabrication challenges

Depending on application requirements, many device optimizations are possible with custom thin-film PZT MEMS printheads, like:

- Inkjet firing frequency

- Droplet size with improved uniformity

- Nozzle density

- Tunable drive voltage

Direct contact

Robbert van der Waal

Business Development Director

MEMS inkjet devices presentation (PDF)

Are you interested in single-pass precision micro-deposition of functional fluids on exotic materials? Such as electrode materials for flexible electronics, photovoltaics and optoelectronics? Check these breakthrough inkjet applications together represent a bright diversified outlook for a potentially disruptive inkjet printing business.

Download the presentation here >

Case study - prototyping with MEMS inkjet technology

Curious about the advantage we deliver to our customers?

Canon Production Printing is active in the printing business, for the next generation of the printing process, they were developing a fluidic MEMS device. It is quite a complex device, which incorporates more than 500 processes and handling steps. It requires quite some capabilities and skills for the partner who does the prototyping.

Watch the video why a major inkjet printing system supplier like Canon Production Printing decided to develop a MEMS inkjet print head with us.

What sets us apart?

- Development of integrated electronics, including specification, design and test of proofs-of-concept ASICs and industrialization support

- Wafer bonding, for MEMS head and MEMS-driver integration

- Module development, integrating MEMS chip, driver electronics, connector, and ink ports

- Full service offering, from device and process development, volume MEMS manufacturing, integration of driver electronics, connector and ink ports to device assembly services: a single partner to obtaining a custom MEMS based inkjet device

- Independent MEMS Foundry – for 30 years we are used to work for industry leaders with high confidentiality and IP protection demands

- High customer satisfaction, NPS score: > 50% (4.5 on a 5-point scale)

How can we help with custom thin-film MEMS inkjet printheads

Robbert van der Waal

Business Development Director

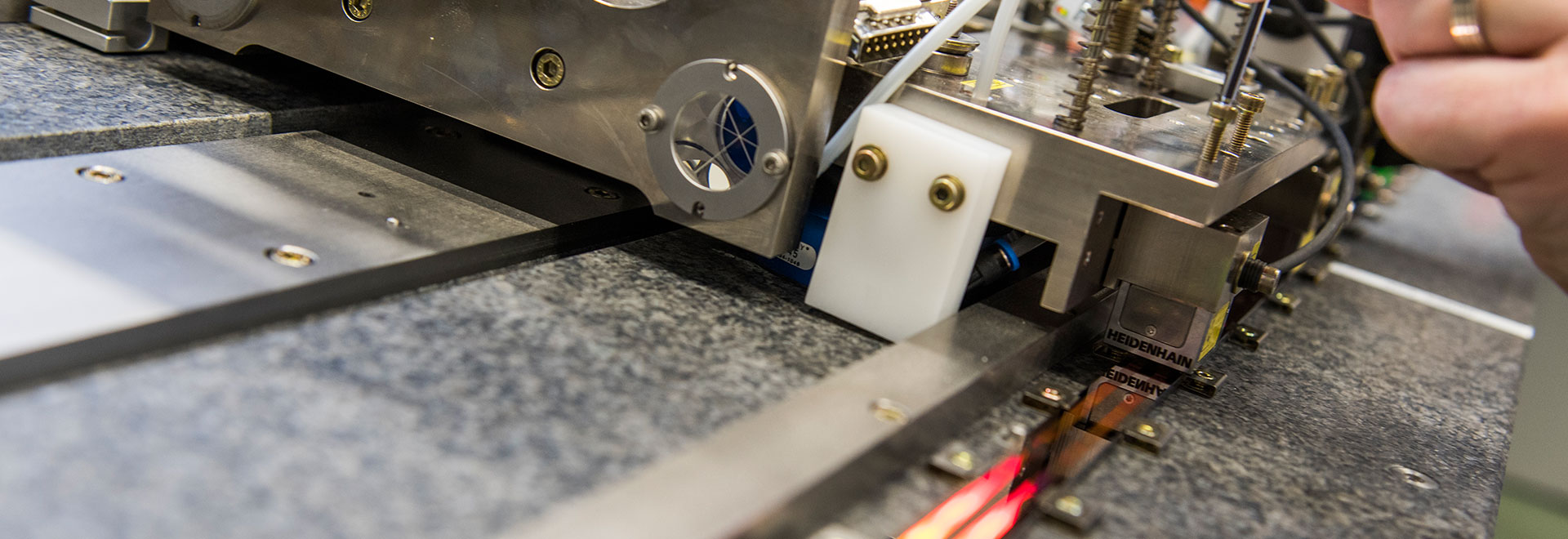

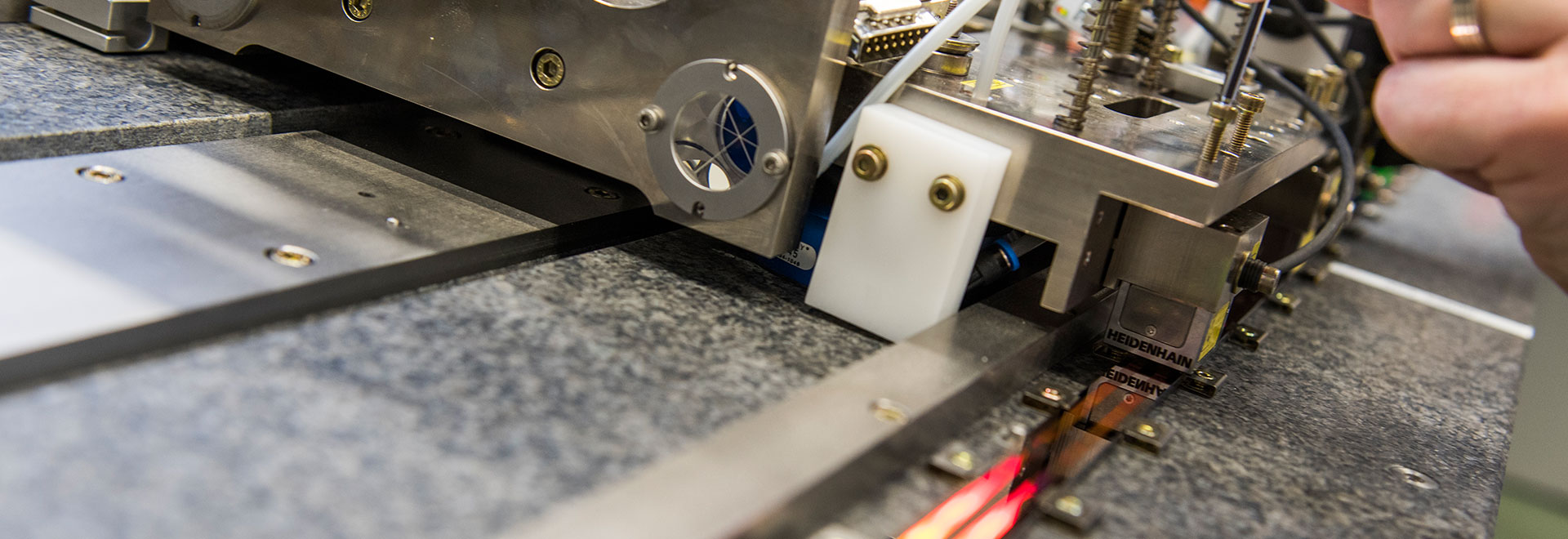

MEMS Foundry

Innovation Engineering operates a state-of-the-art 2650 m2 pure-play MEMS Foundry on the High Tech Campus in Eindhoven, the Netherlands (see background picture). The MEMS Foundry is specialized in low to medium volume custom MEMS manufacturing.

MEMS & Micro Devices expertise

Our 140 experts design, develop and manufacture custom microelectromechanical systems (MEMS) and assemble micro devices. We follow a phase-gated approach; from demonstrating feasibility and giving proof of concept, up to manufacturing your devices with the right quality.