MEMS & Micro Devices applications

The complexity of MEMS can be seen by the extensive range of different markets and applications. For instance, MEMS can be found in systems ranging across automotive, medical, electronical, communication, semi-conductor, defense, aerospace, and more.

Some examples of current MEMS devices include accelerometers for airbag sensors, inkjet printer heads, computer disk drive heads, projection display chips, blood pressure sensors, optical switches, microvalves, biosensors and many other products that are all manufactured in high commercial volumes.

As an emerging technology, new applications for MEMS products are being discovered continuously. Therefore, it is usually our customer that brings market and application knowledge to the table. Together with our expertise on technology and methodology, we can realize their innovative ideas.

Are you contemplating the use of MEMS devices in your system in order to create a sustainable competitive advantage? When your current solution just doesn’t seem to do the trick, a custom MEMS might be worthwhile investigating. How feasible would a custom MEMS be for you?

Contact our expert

Robbert van der Waal

Business Development Director

Key application areas

New digital printing application areas, breakthrough technology & cost advantage with custom thin-film MEMS inkjet printheads.

Breakthrough applications for ultrasound, complementing conventional technology with advantages.

In house expertise to shorten your photonics development time and help you achieve consistent products at volume scale.

RF application design: modeling & simulation, layout, thermal management, EMC, antenna design, signal integrity, wireless reliability, functional testing.

For microfluidic devices we manufacture a range of devices like meshes, nozzles, jets, channels, barriers, and complete functional chips.

How to succeed in BioMEMS development and manufacturing? Benefit from unique BioMEMS expertise that has helped leading BioMEMS companies successfully turn their imaginative ideas into working devices.

Our thin film capabilities allow us to act as a pure-play foundry for a wide range of MEMS devices & actuators.

Micro-fabricated devices are finding their way to the front-end of medical equipment, interfacing between body and machine and enable better and cheaper diagnostic equipment.

Our technology platform for micro- and nanotechnologies is very suitable for the manufacturing of MEMS sensors for measuring flow, pressure, temperature or acceleration.

A typical example of micro devices with high potential in e.g. analytical and healthcare applications are micro sieves.

In an organ-on-a-chip a human organ is reproduced in its most elementary form, designed to reproduce relevant physical factors in the human body.

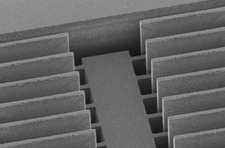

Sensor and actuator applications: large area high-precision silicon gratings for IR spectral analysis, outcoupling of light from solid-state lasers via microlenses, special coatings, or light guidance in silicon waveguides.

For RF applications we have made several MEMS applications like micro-machined micro-wave cavity filters, submounts, interposers and devices for RF front-end protection.

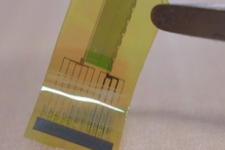

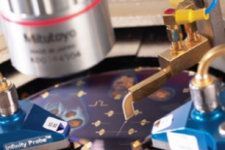

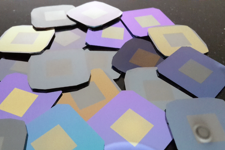

We offer several services on 6” wafers (max), typically provided by the customer. See how this could benefit you?

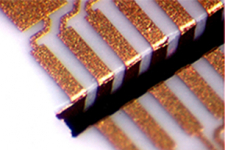

Employing our state-of-the-art tools, our ability to use a wide variety of materials (Ag to Zn, dielectrics, polymers) and substrates (Si, III/V, glass, ceramic; square & round, up to 8”), we manufacture according to your requirements.

Process development and manufacturing of ultra-thin film membranes and windows.

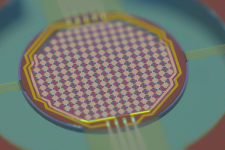

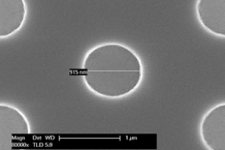

Customer case - creating nanowire technology for solar applications

Sol Voltaics AB provides next-generation solar nanotechnology solutions that can significantly enhance solar panel efficiency.

High quality wafers and shortened time to market were the main goals to partner up. We helped Sol Voltaics AB by developing a robust process flow to manufacture patterned substrates.

Their application is quite unique, therefore we needed to adopt specific requirements to meet those requests and specifications.

Watch the video to see how

Let us know your MEMS & Micro Devices applications questions

Robbert van der Waal

Business Development Director

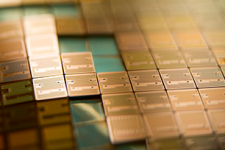

A MEMS Foundry and Micro Devices Facility working as one-stop shop

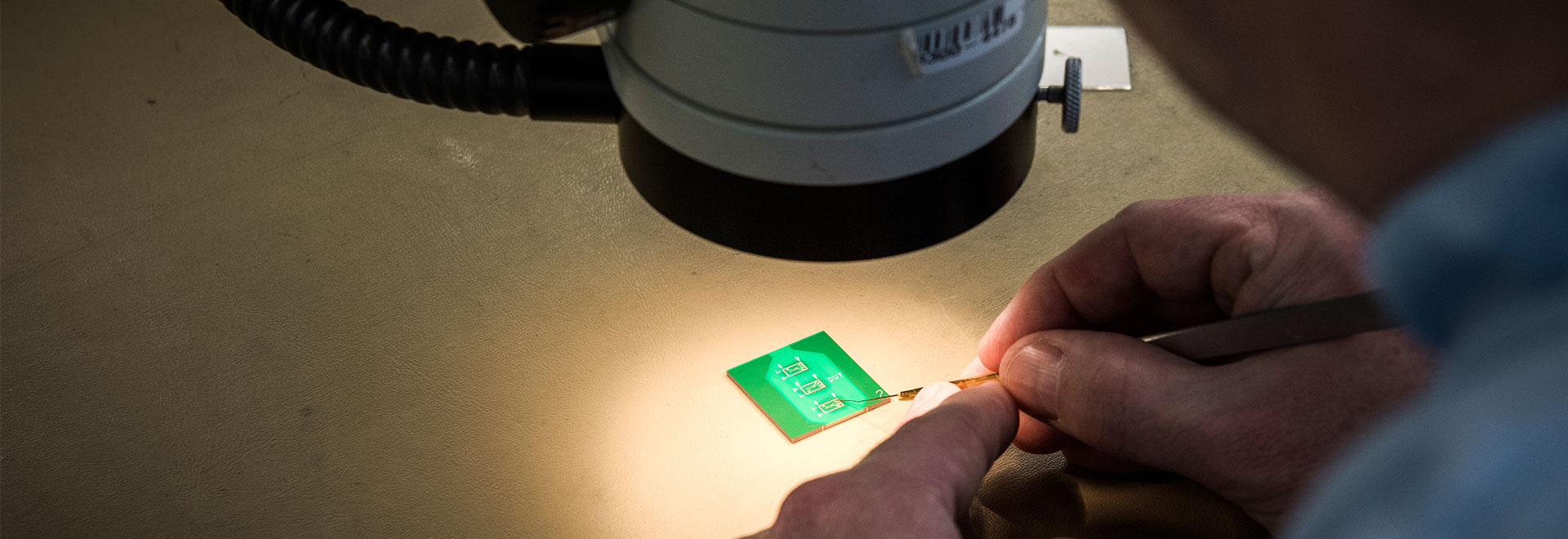

We offer both MEMS foundry and Micro devices assembly as a one-stop shop, which allows our partners to have one point of contact for efficient communication and project handling. It is pretty unique that the two entities can collaborate together, within 5km distance in Eindhoven. MEMS component & micro assembly can really be optimized for each other at Philips Innovation Services.

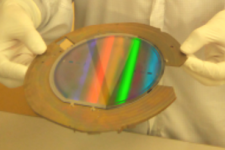

Philips Innovation Services operates a state-of-the-art 2650 m2 pure-play MEMS Foundry on the High Tech Campus in Eindhoven, the Netherlands. This MEMS Foundry is specialized in low to medium volume custom MEMS manufacturing. When off-the-shelf components do not meet your requirements, and you consider having a custom MEMS device especially made for you, you come to us.

At the Micro Devices Facility The Greenhouse located at Strijp in Eindhoven, the Netherlands, we have over 40 years of experience. We deliver key microsystem modules, integrated into devices, for the medical & high-tech markets. Our customers typically require a complex combination of technologies to obtain new advanced functions at small scales.