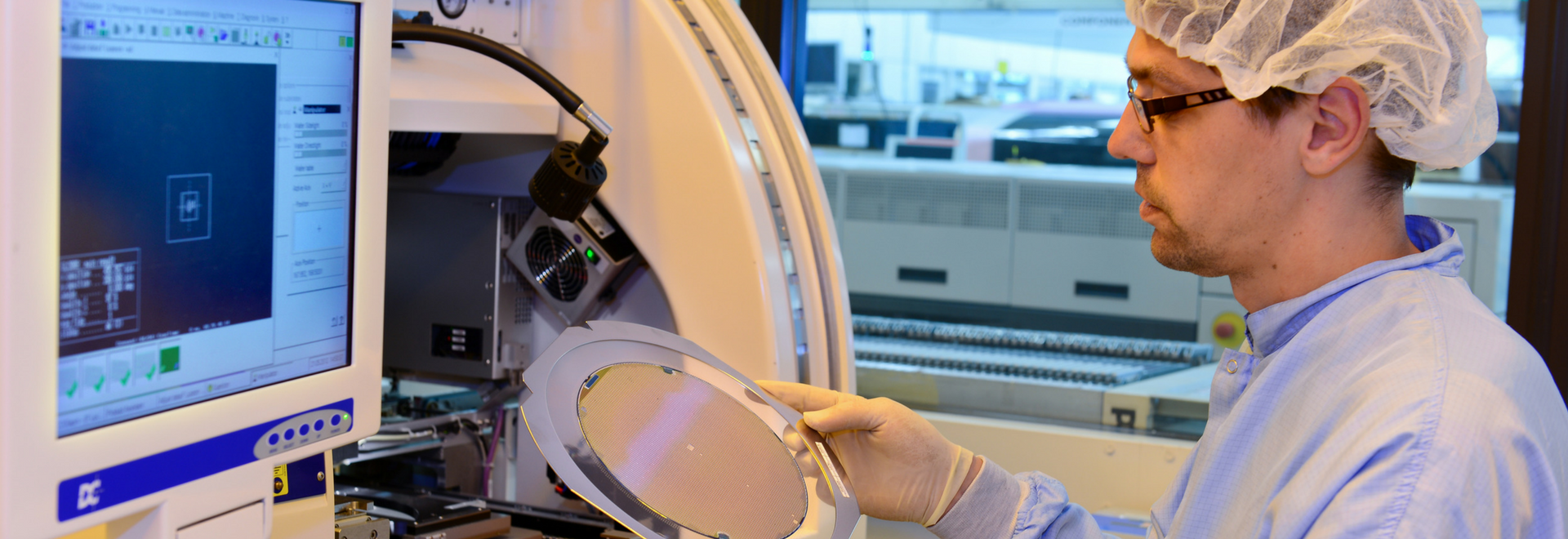

Interconnect architecture & prototyping

Your benefit

Your concept typically requires the integration of active elements and electrical functionality by a variety of more than 2D interconnect & bonding technologies to create your new, unique function. The combination of odd shape and non-conventional substrates enables you to enter new opportunities.

We deliver

A one-stop-shop covering a broad range of interconnect technologies to create new unique functions. With our know-how, experience and systematic approach, we have the flexibility to manufacture prototypes and are able to develop a reliable and optimized production flow for your unique product.

Our approach

We use a phase-gated approach from prototyping to production, using DfX to address from the start items like critical-to-quality parameters and new, critical processes. We do this in close cooperation with you customer as we strongly believe that a strong integral design and quality can only be achieved in co-development with each other.

Methodologies

- DfX (design for excellence)

- Concept creation and technology scoping

- Technology selection: wafer dicing, die attach, wire-bonding, stud bumping, ACF bonding, soldering

- Inspection and failure analysis: 3D automated optical or X-RAY

- Functional testing

- Risk management, FMEA

- Verification & validation of process and tooling

Check out our related services

When you need a custom MEMS device for your system, you can rely on our experts. Their expertise is to really understand your requirements, to show feasibility and proof of concept, develop the product and required process in a stage-gated manner and reproduce reliably & controlled.

We have over 30 years of experience in prototyping & assembly in our Micro Devices Facility called ‘Greenhouse’. Therefore, integral coupling with supply chain and manufacturing activities is assured.